Industry News

-

Why is heat treatment necessary for machining?

I. Why metal heat treatment Speaking of metal heat treatment, you can’t get around iron, which is the most abundant metal on our planet and the most widely used metal. Pure iron refers to the carbon content of less than 0.02% iron metal, is a flexible and ductile silver-white metal, has a g...Read more -

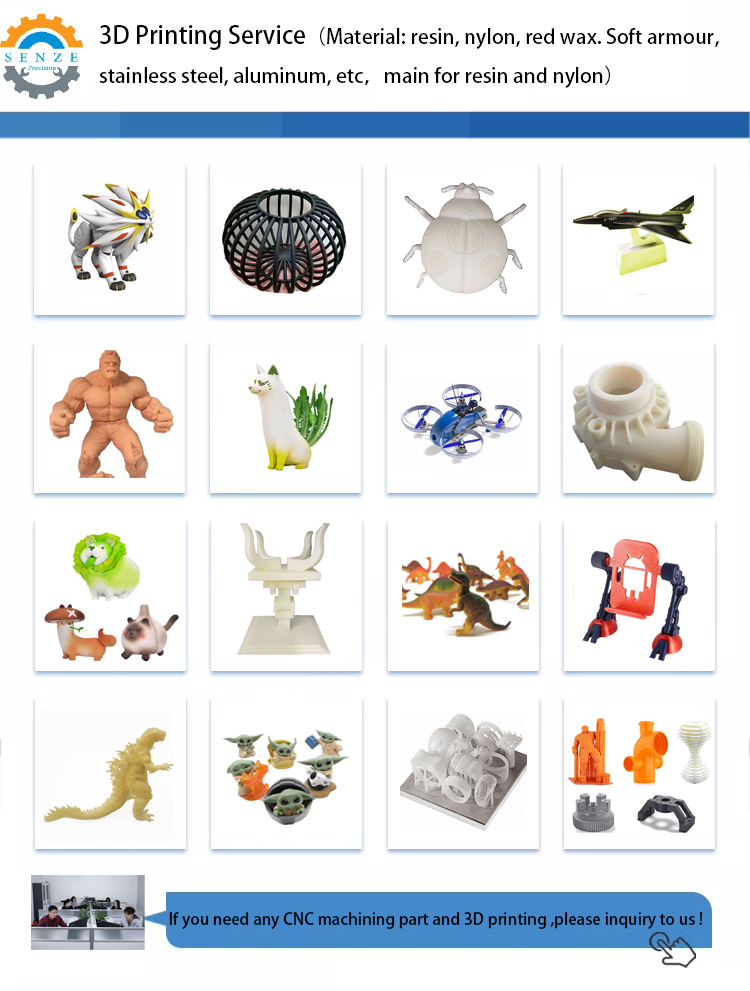

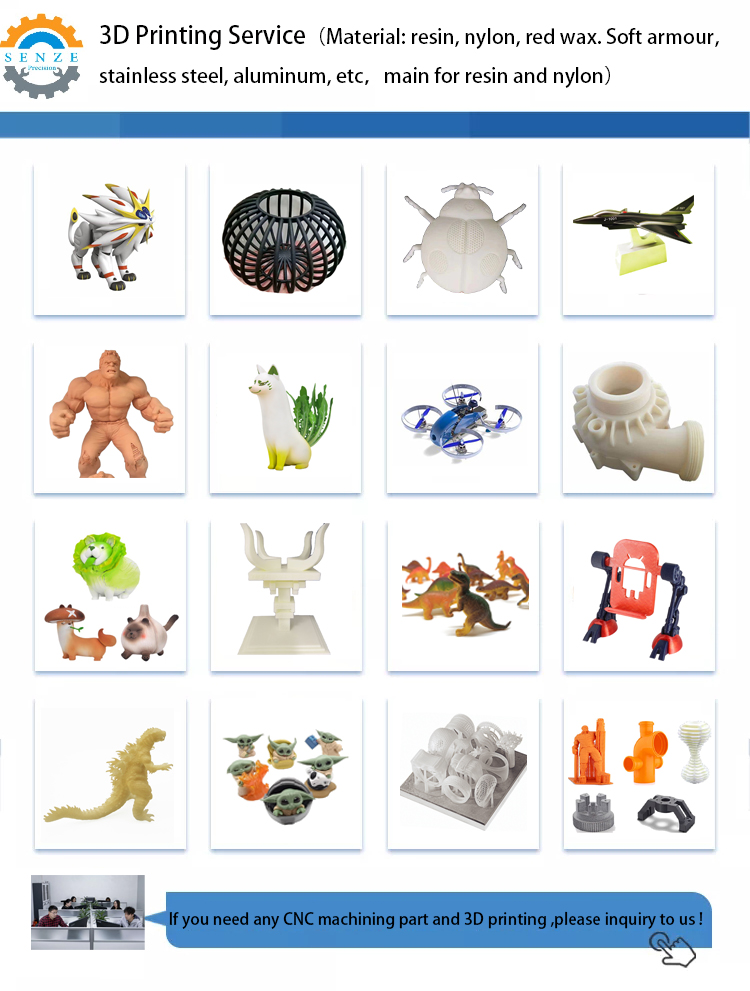

What is the difference between CNC machining and 3D printing?

1. Differences in materials: 3D printing materials mainly include liquid resin (SLA), nylon powder (SLS), metal powder (SLM), gypsum powder (full color printing), sandstone powder (full color printing), wire (DFM), sheet (LOM) and many more. Liquid resins, nylon powders and metal powders account ...Read more -

Die-casting Process

The die-casting process is a process of unifying pressure, speed and time using three major elements: machine, mold and alloy. For metal thermal processing, the presence of pressure is the main feature that distinguishes the die casting process from other casting methods. Die casting is a special...Read more -

Sand Blasting-One Kind Of Surface Finish

Sandblasting is a process of cleaning and roughening the surface of a substrate by the impact of high-speed sand flow. Compressed air is used as power to form a high-speed jet beam to spray materials (copper ore, quartz sand, emery, iron sand, Hainan sand) to the surface of the workpiece to be tr...Read more -

SLM 3D Printing Technology

SLM, the full name of selectivelasermelting, is mainly used in molds, dentures, medical, aerospace, etc. Metal 3D printing is equipped with 500W fiber laser, with collimation system and high-precision scanning galvanometer, fine spot and optical quality can be obtained, so SLM metal 3D printing h...Read more -

What are the causes of scratches when CNC machining parts?

CNC lathe machining, or CNC parts processing machine, is a machining machine used by our machining manufacturers. Oftentimes, scratches appear when CNC lathes are machining parts! Redo! Now let us Senze precision give you the answer to the reasons for the scratches on the parts processed by CNC l...Read more -

What is 5-axis CNC machining?

A 5-axis CNC machine moves cutting tools or parts along five axes at the same time. Multi-axis CNC machines can manufacture parts with complex geometries, as they offer two additional rotational axes. These machines eliminate the need for multiple machine setups. What are the advantages a...Read more -

Injection Molding-One Of processing technology from Senze

Injection molding is a method of producing shapes for industrial products. The injection molding process is a process technology, mainly a variety of processes that transform plastics into various desired plastic products. The principle is that granular and powdery plastic raw materials are adde...Read more -

Custom CNC Machining Milling Turning CNC Lathe Service Parts

What is CNC Machining? For businesses that require a lot of custom parts there’s one term you’re likely to run across on a regular basis: CNC Machining. CNC machining is a critical component of modern manufacturing. There are many reasons why opting for CNC machining is beneficial, which is why ...Read more -

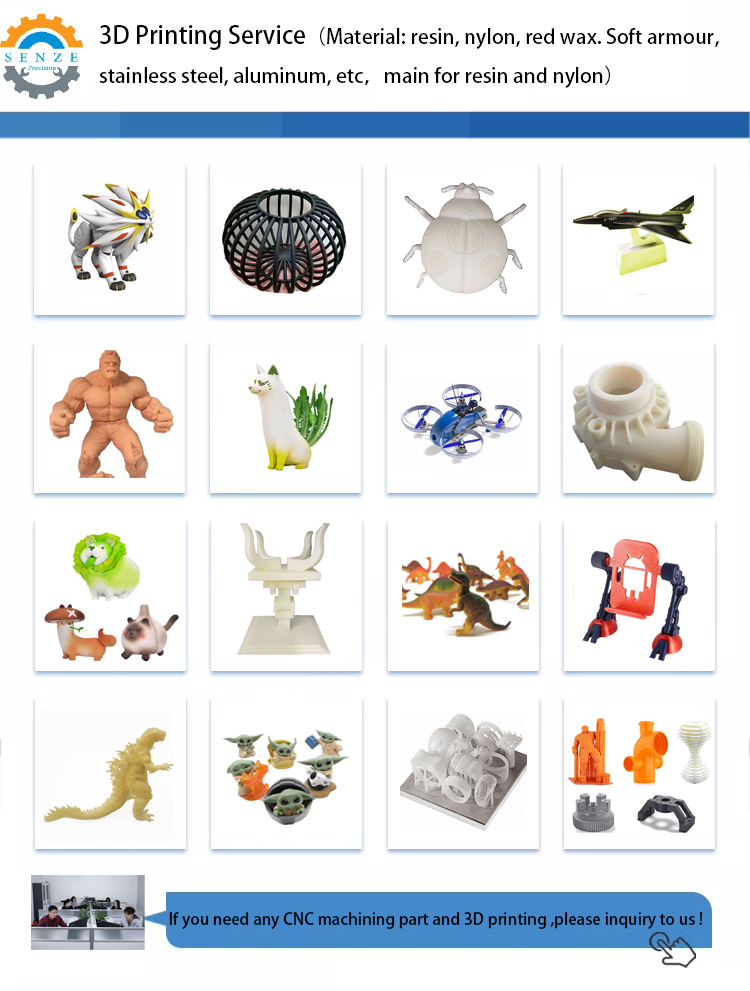

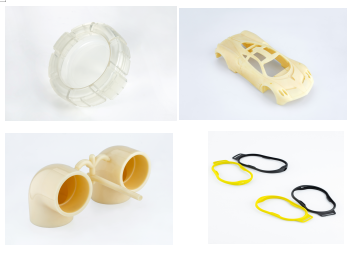

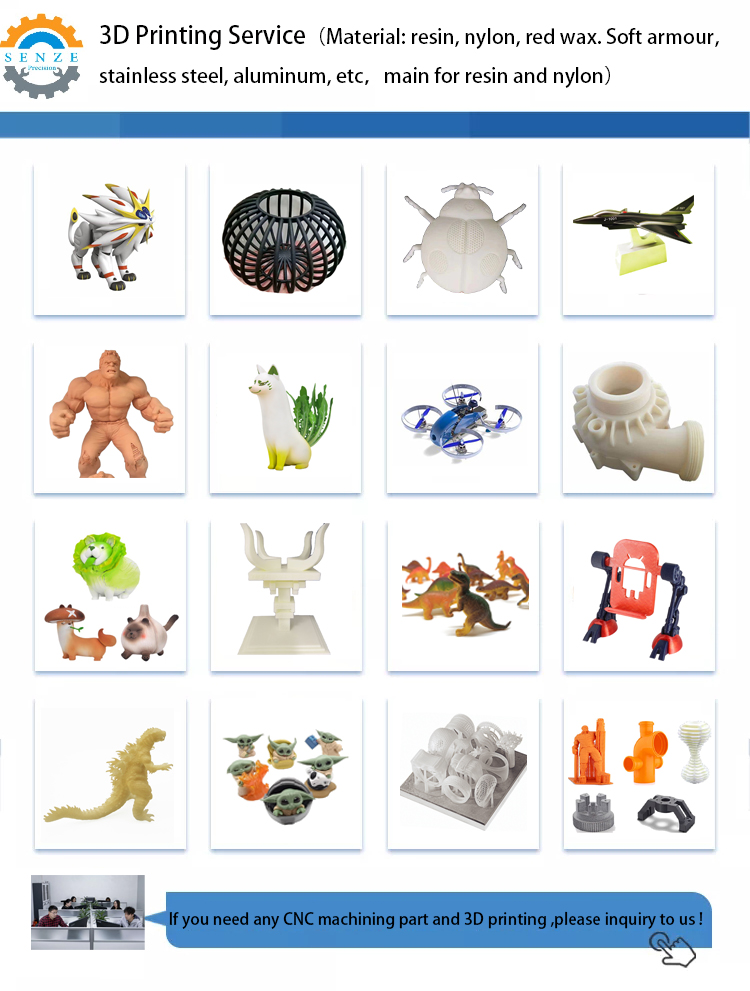

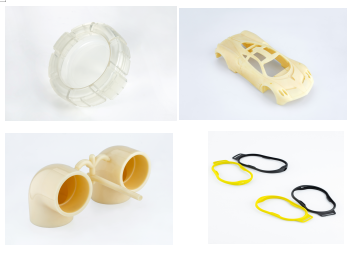

3D Printing Technology—Rapid Prototyping Products

The beauty of 3D printing technology is that it does not need to be operated in a factory, desktop printers can print small items, and people can put them in a corner of an office, a store or even a house; and large items such as bicycle frames, car steering wheels and even aircraft parts , a lar...Read more -

3D Printing Technology

3D printing technology, which is a kind of rapid prototyping technology, is a technology of constructing objects by layer-by-layer printing using adhesive materials such as powdered metal or plastic based on a digital model file. In the past, it was often used to make models in the fields of mo...Read more -

Anodizing—One Kind Of Surface Treatment

Anodizing is a metal surface treatment process.it can be used in CNC machining parts , It refers to a material protection technology that forms an oxide film on the surface of a metal material in an electrolyte solution by applying an anodic current, also known as surface anodic oxidation. A...Read more -

Heat treatment-one kind of process in the CNC machining parts

Heat treatment is a process in which metal materials are heated, kept warm and cooled in a certain medium, and their properties are controlled by changing the metallographic structure on the surface or inside of the material. Process characteristics Metal heat treatment is one of the important pr...Read more -

Heat treatments for CNC machined parts

Learn how heat treatments can be applied to many metal alloys to drastically improve key physical properties like hardness, strength and machinability. Introduction Heat treatments can be applied to many metal alloys to drastically improve key physical properties (for example hardness, strength o...Read more -

Aluminium CNC machining processes

You can machine aluminium by a number of the CNC machining processes available today. Some of these processes are as follows. CNC Turning In CNC turning operations, the workpiece rotates, while the single-point cutting tool stays stationary along its axis. Depending on the machine, either the wor...Read more