News

-

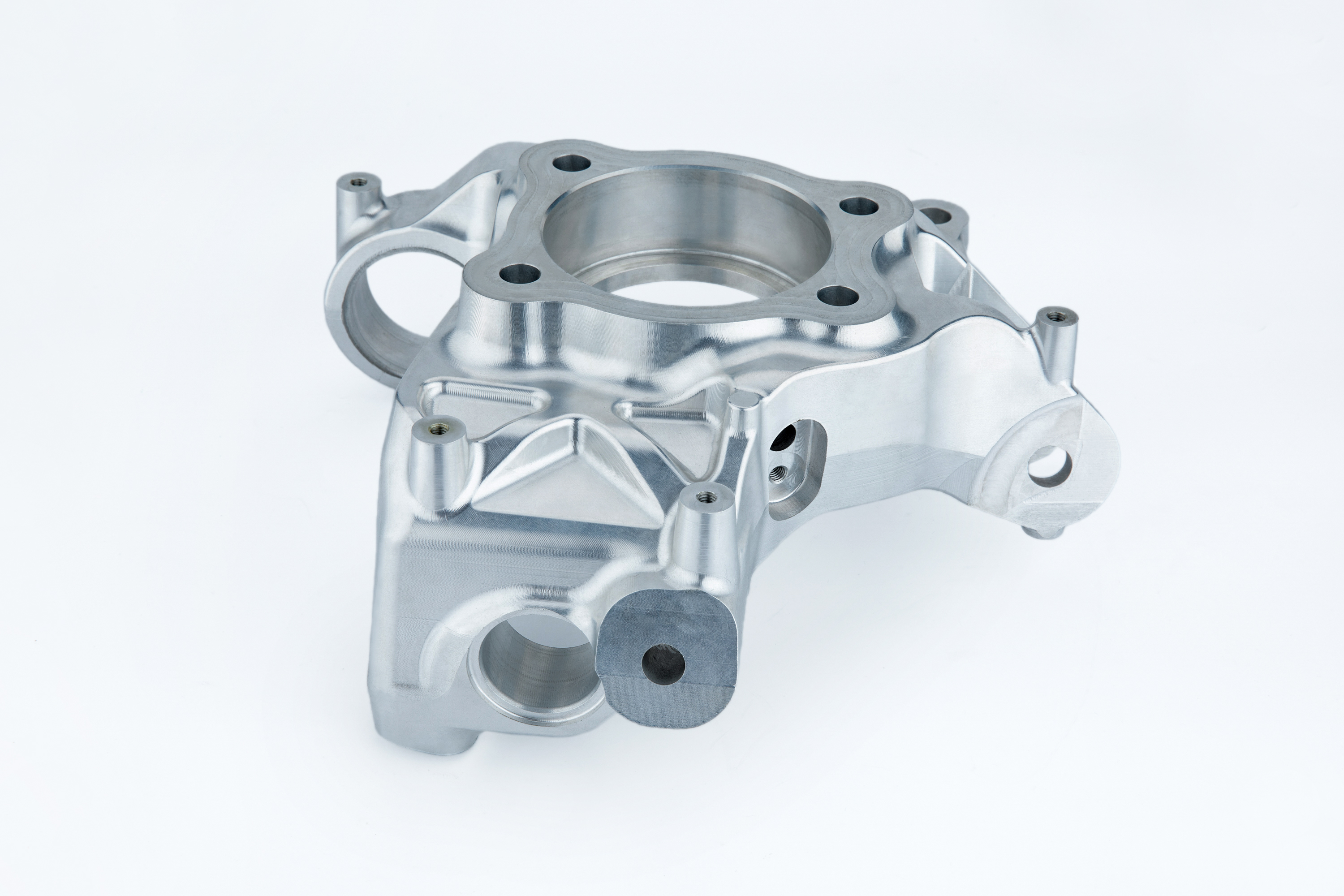

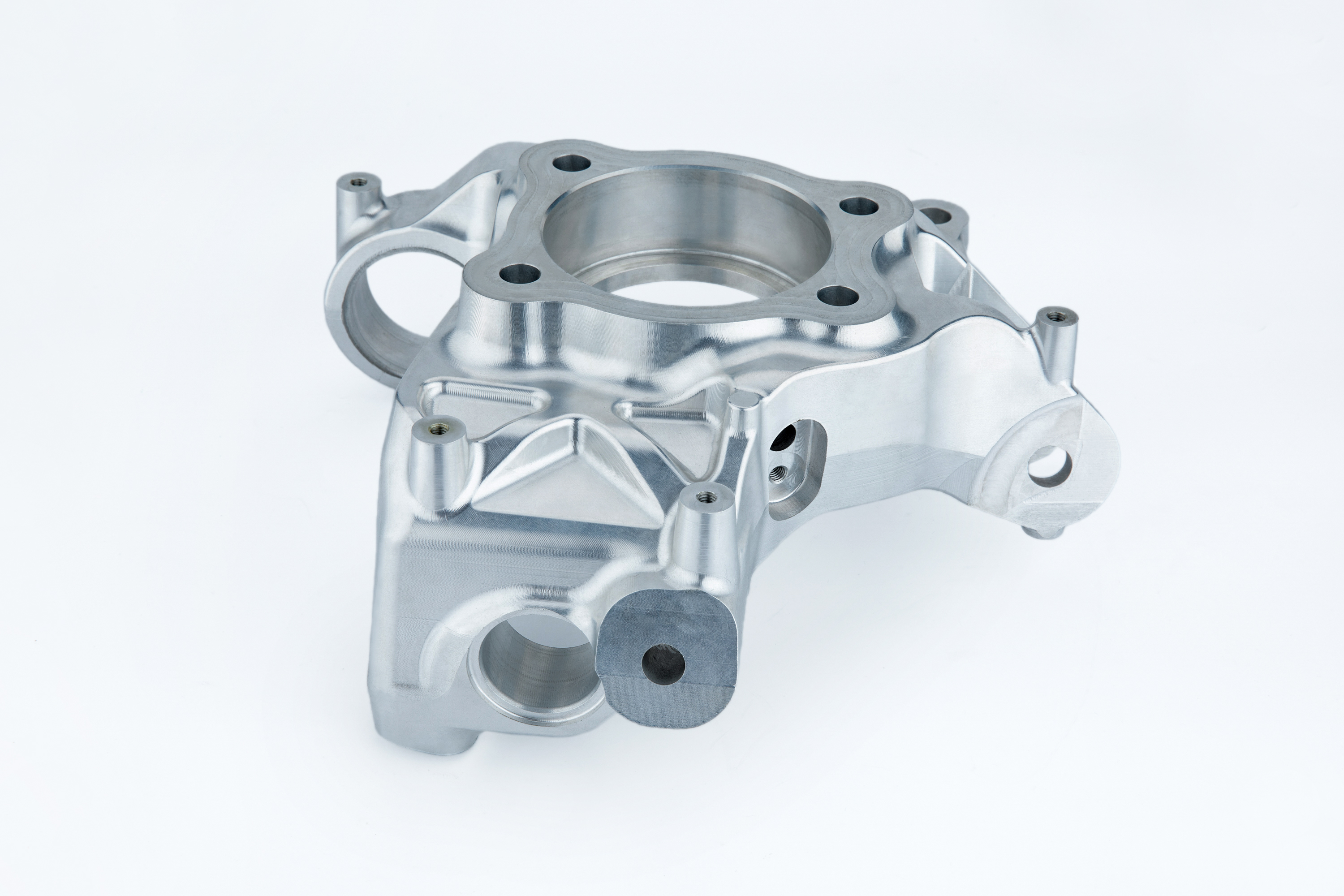

Aluminium CNC Post-machining processes

Post-machining processes After machining an aluminium part, there are certain processes that you can carry out to enhance the physical, mechanical, and aesthetic features of the part. The most widespread processes are as follows. Bead and sand blasting Bead blasting is a finishing process for aes...Read more -

Abrasive blasting/ Sandblasting treatment

Abrasive grit blasting, or sand blast cleaning, is a surface treatment process widely used in a variety of different industries with many diverse purposes. Abrasive blasting is the process by which an abrasive media is accelerated through a blasting nozzle by means of compressed air. The abrasive...Read more -

CNC Machining of Aluminium

Aluminium is one of the most machined materials available today. In fact, aluminium CNC machining processes are second after steel in terms of frequency of execution. Mainly this is due to its excellent machinability. In its purest form, the chemical element aluminium is soft, ductile, non-magnet...Read more -

Surface finish in cnc machining

CNC milling and turning are versatile, cost-effective and accurate, yet the possibilities for CNC machined parts expand even further when additional finishes are considered. What are the options? While that sounds like a simple question, the answer is complex because there are so many factors to ...Read more -

History and terminology of metal machining

History and terminology: The precise meaning of the term machining has evolved over the past one and a half centuries as technology has advanced. In the 18th century, the word machinist simply meant a person who built or repaired machines. This person’s work was done mostly by hand, using p...Read more -

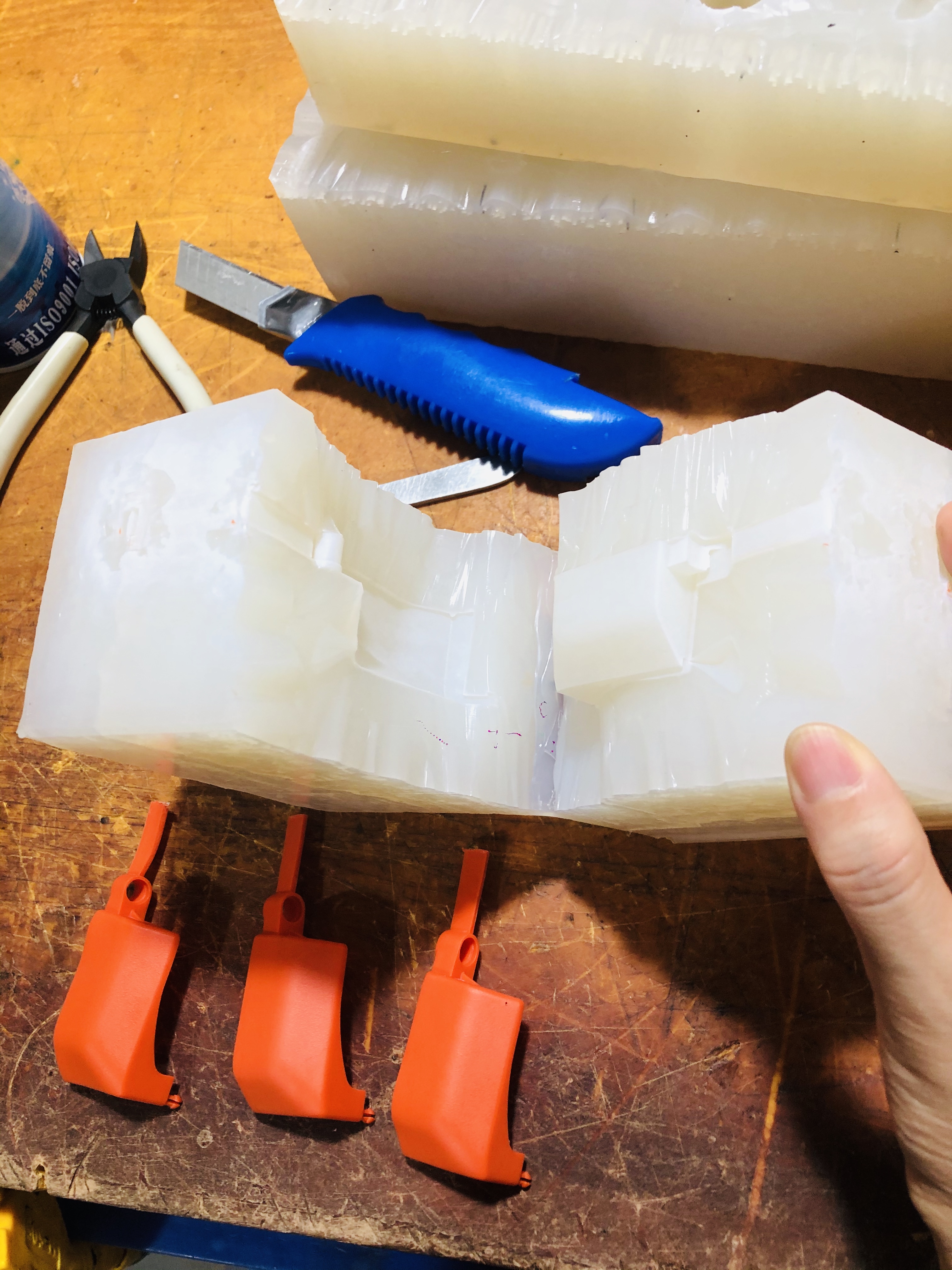

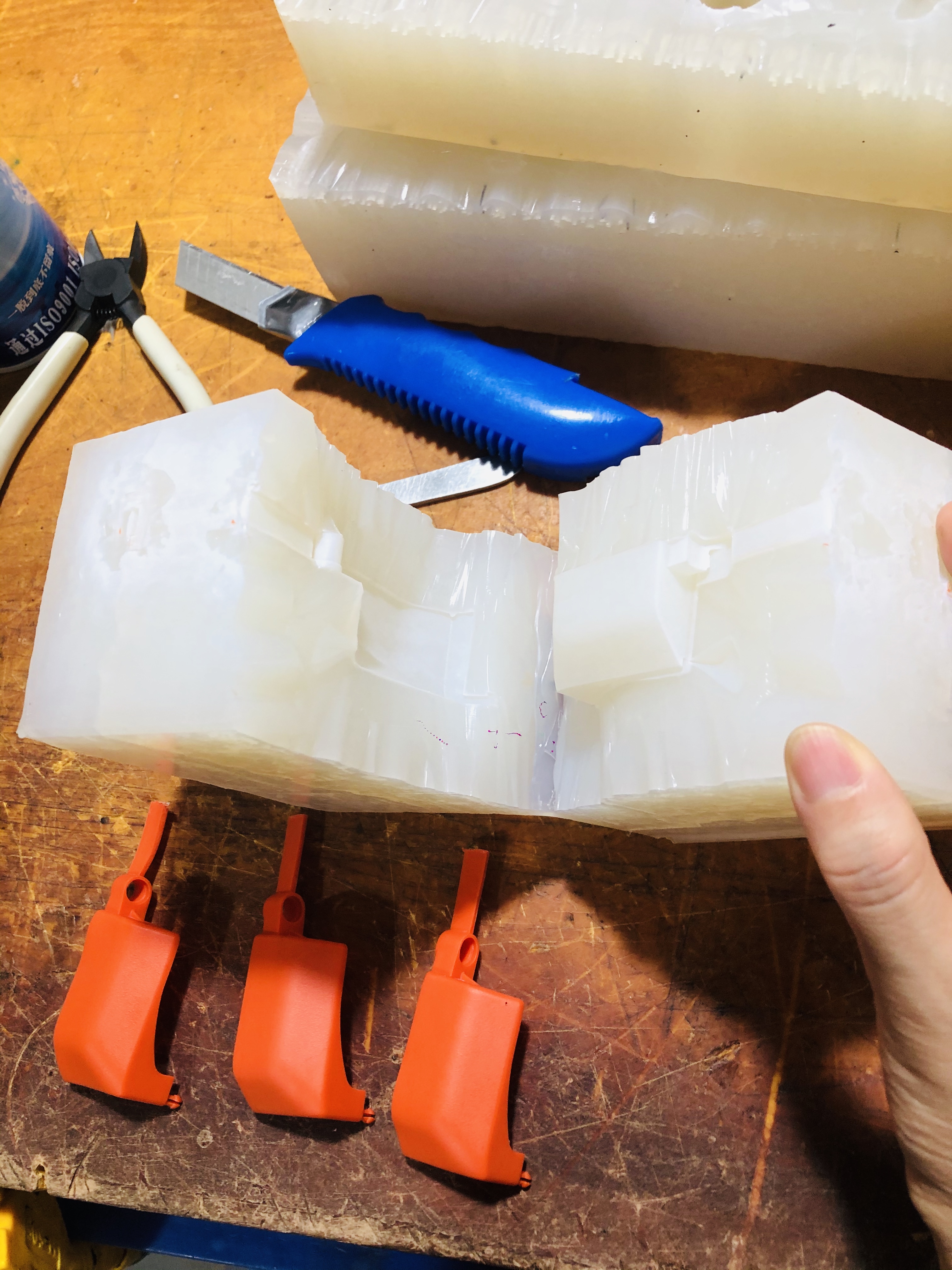

What is Vacuum Casting? And the Benefits of Vacuum Casting

If you are wondering which is the most economical way to make any prototype? Then you should try vacuum casting. In vacuum casting, you’re require to have the correct optimum temperatures when curing the materials. For resin, you require 30 degrees Celsius to minimize shrinkage at vacuum pressure...Read more -

Rapid prototyping

A rapid prototyping machine using selective laser sintering (SLS) 3D model slicing Rapid prototyping is a group of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer aided design (CAD) data. Construction of the part or assembly is us...Read more -

The affect of precision machining to the future state of medical devices

Precision machining is found in a variety of sectors, including electronics, aircraft, and healthcare. CNC machines are used to make a lot of medical components and devices. The medical equipment industry consists of various medical parts, such as implants for spine reconstruction, knee, and hip ...Read more -

Black oxidation precision prototype

Black oxide or blackening is a conversion coating for ferrous materials, stainless steel, copper and copper based alloys, zinc, powdered metals, and silver solder.[1] It is used to add mild corrosion resistance, for appearance, and to minimize light reflection.[2] To achieve maximal corrosion res...Read more -

How does 3D printing work?

While debate rages on technology forums across the web about if, when and how 3D printing will change life as we know it, the big question most people want answered about this most hyped of hyperbolic technologies is a much more straightforward one: how, exactly, does 3D printing work? And, belie...Read more -

The Differences – CNC Milling vs CNC Turning

One of the challenges of modern manufacturing is understanding how different machines and processes function. Understanding the difference between CNC turning and CNC milling allows a machinist to use the right machine to achieve the best results. In the design stage, it allows CAD and CAM operat...Read more -

Why Is It So Useful in the Precision Prototype Manufacturing Industries to Use CNC Machines?

With process automation now recognized as critical for uniformity and efficiency, CNC machines have become necessary tools, particularly in the manufacturing industry. Computer numerical control (CNC) machines are widely used in the manufacturing industries to control movement of production equip...Read more -

CNC precision parts manufacturer talk about the basic requirements of machining parts

Nowadays, customers who process mechanical parts have relatively high requirements. General precision machining cannot meet their requirements. Custom-made high-precision parts have become their inevitable choice. Under the condition of sufficient assets, such customers will definitely choose to ...Read more -

How to ensure the quality of precision machining parts?

In the specific application of precision parts, the higher the precision, the more exquisite, the more it can reflect the machinability and quality. At the same time, this product is also more favored by customers. Generally speaking, CNC machining centers have incomparable advantages in producti...Read more -

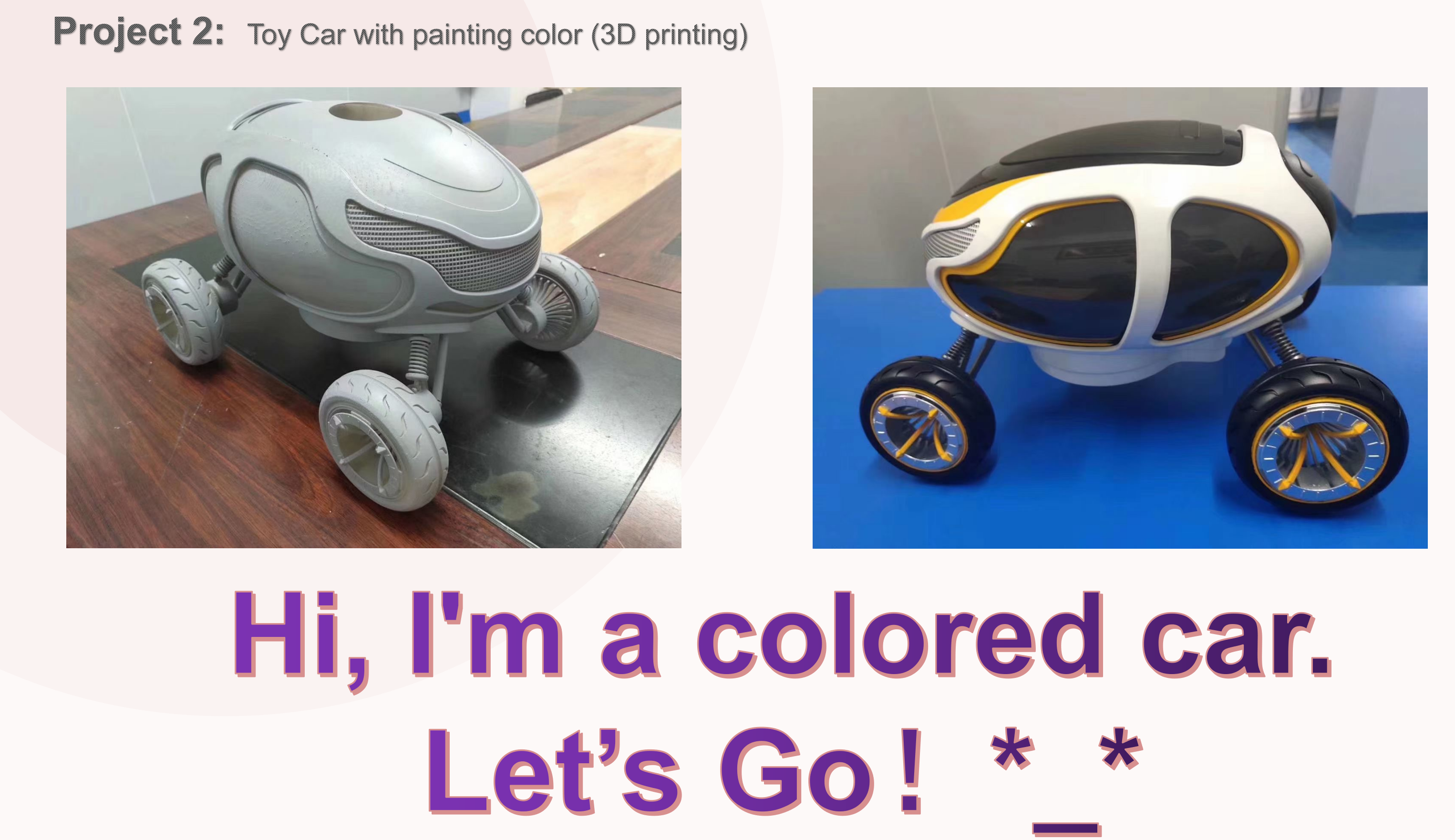

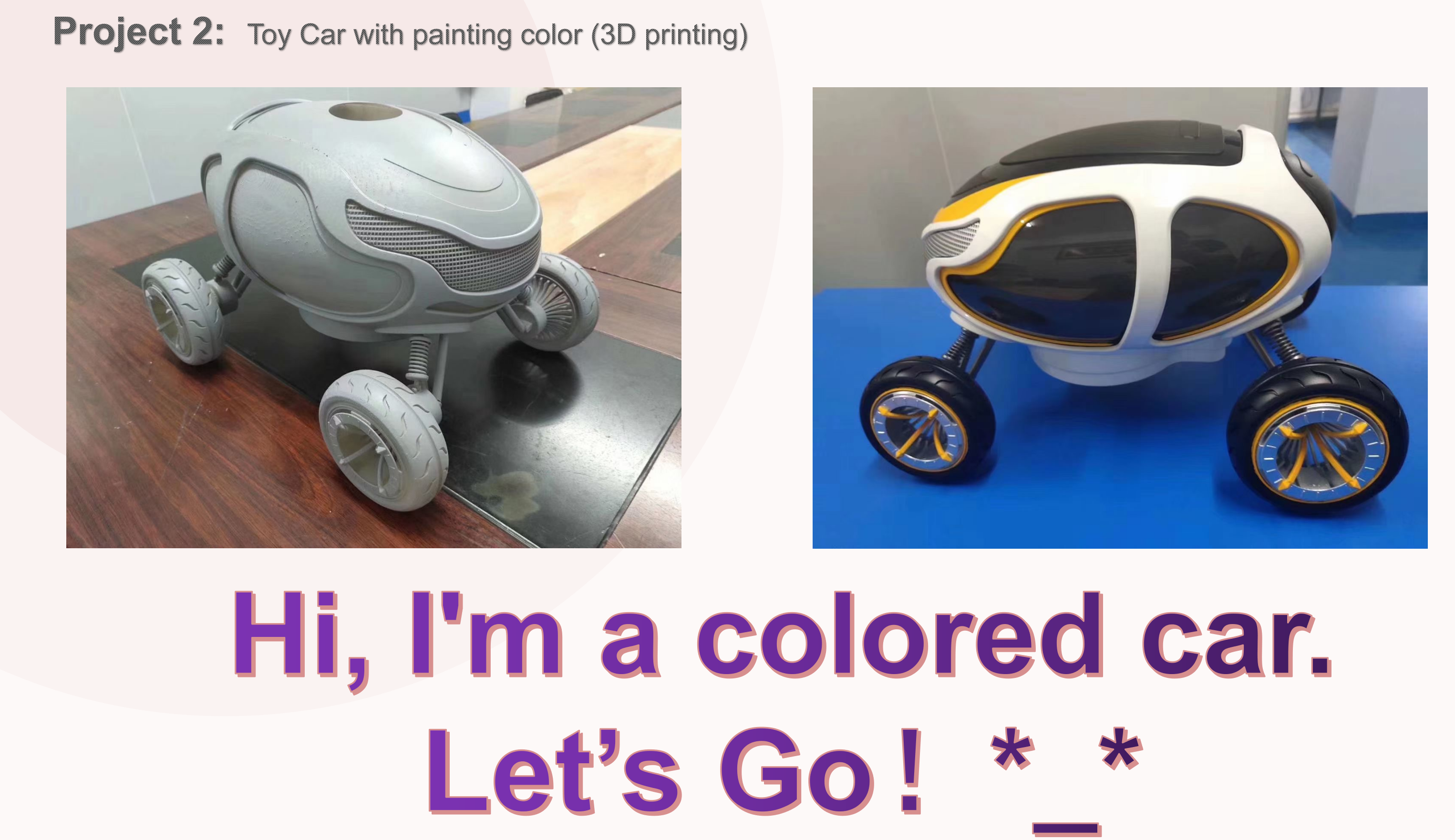

3D printing Toys Car

Introduction for 3D printing: What is 3D printing? 3D printing is an additive technology used to manufacture parts. It is ‘additive’ in that it doesn’t require a block of material or a mold to manufacture physical objects, it simply stacks and fuses layers of material. It’s typically fast, with ...Read more