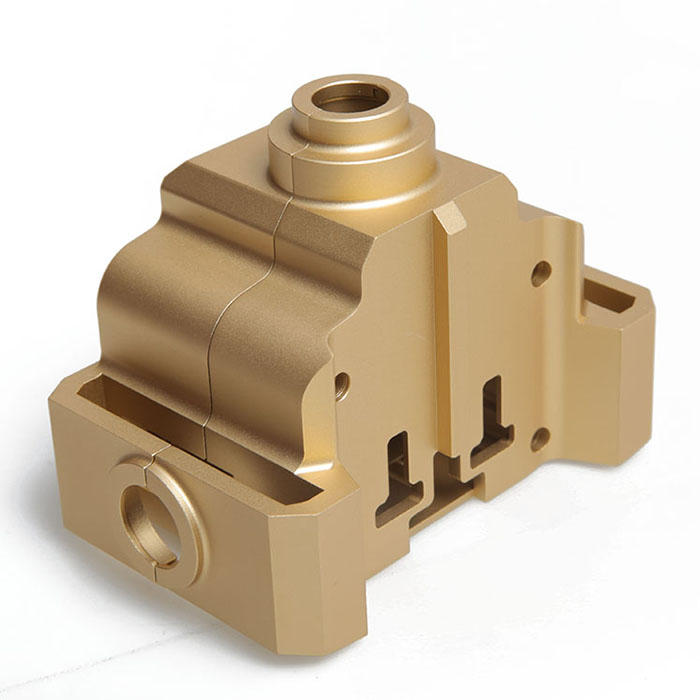

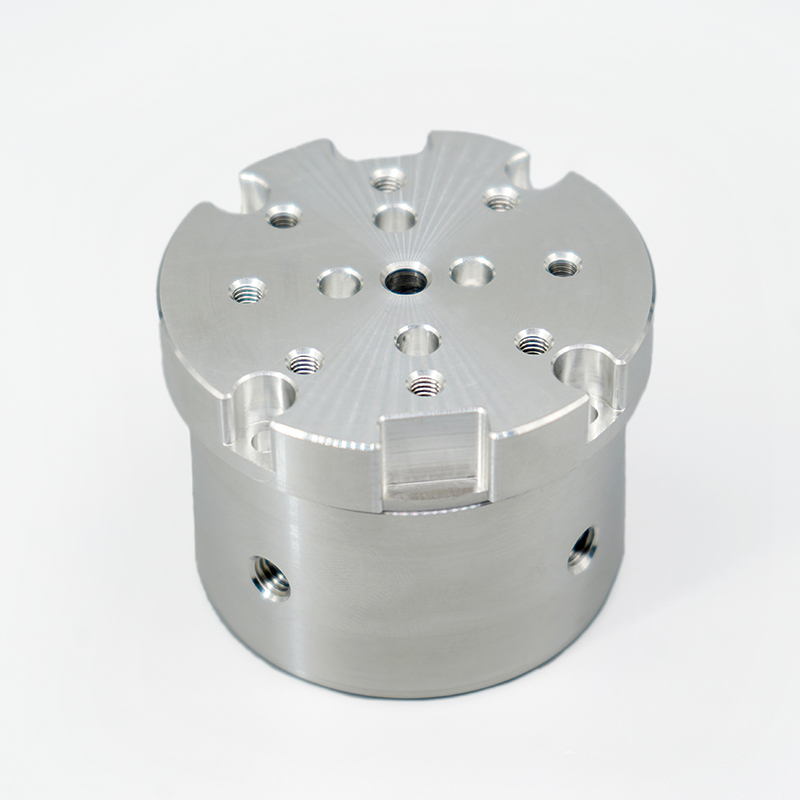

High Precision Aluminum Custom CNC 5 Axis Machining Parts – Senze

High Precision Aluminum Custom CNC 5 Axis Machining Parts – Senze Detail:

What is 5-axis machining?

5-axis machining refers to the use of a computer numerical control (CNC) to simultaneously move cutting tools or parts along five axes. The cutting tool continuously moves along every axis so that the tip is always perpendicular to the part. This process allows you to machine a variety of complicated parts.

An Explanation of the 5 Axes

You may already be familiar with 3-axis machining. If you’re not, it’s fairly simple–it’s a machine that moves sideways on the X-axis, vertical on the Y-axis, and back-and-forth on the Z-axis. With 5-axis machining, you get two more axes: the tilting table (A-axis) and the table rotation (C-axis)

The advantage of Senze Precison

1. Custom machining meet to your requirements,

2. Small order quantity acceptable

3. Quickly feed back to all your questions

4. Lead time : sample is about 7days, mass production is about 20-30 days (according to the quantity and technical)

Material Used for 5-axis machining parts

1. Steel alloy, Carbon steel, Stainless steel

2. Copper alloy, brass, bronze

3. Plastic, UPE, PVDF, ESD plastic, Teflon

4. Aluminium alloy, AL6061, AL7075, AL6063, AL5083, AL2012.

Surface finish for cnc machining

Polishing, Anodized, Anodizing, Bead sand blasting, Chrome plated, Powder coated, PVD coating, Etching, Titanium coated, Vacuum coating, Nickel plating, Zinc plated, Chrome plated, Oxide black, and so on.

What do we have for cnc machining

1.5/4/3 axis CNC machining

2.CNC turning machining.

3.Injection molding, Die cast molding

4.Sheet metal fabricate, laser cutting service.

5.Surface treatment

6.QC test system: VMS/CMM QC inspection

7.Certification We have:ISO9001:2015

Working process for cnc machining

We have rich experience in precision machining industry, custom machining match your design.

Senze Precision Machining provides full-service machining for many types of materials and can support your large and small part needs. Custom precision CNC turning and milling service, and we also provide high precision 5-axis service. You will get high quality turned parts, milling parts, cnc parts. Such as housing, connectors, tube fittings, dowel Pin, drive shaft, flange, ring, cylinder body, etc.

Request a quote on CNC machining parts for your application, or contact us for more information production.

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" and the theory of "quality the basic, belief the very first and management the advanced" for High Precision Aluminum Custom CNC 5 Axis Machining Parts – Senze , The product will supply to all over the world, such as: Lisbon, Argentina, Belarus, We have won a good reputation among overseas and domestic clients. Adhering to the management tenet of "credit oriented, customer first, high efficiency and mature services", we warmly welcome friends from all walks of life to cooperate with us.

CNC Machining Parts

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.